What is DCBP?

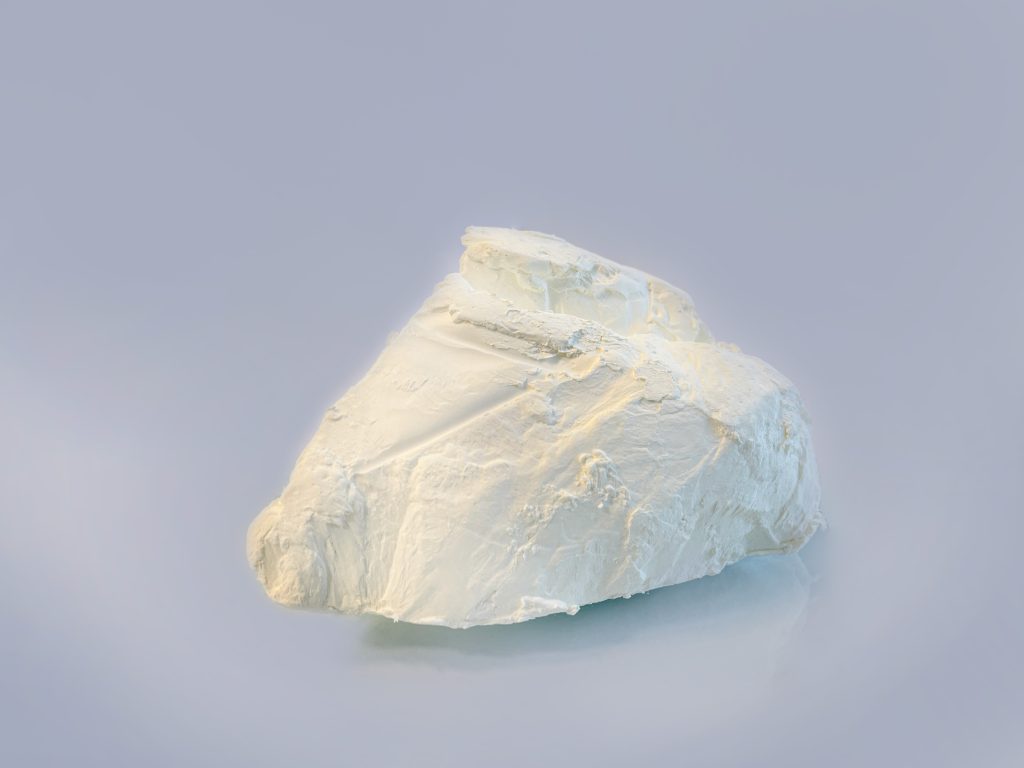

DCBP is a widely used organic peroxide in the production of silicone extrusion products. DCBP is a white, pasty material that should be stored below 30 degrees Celsius due to its flammability.

Home / DCBP

Bis-(2,4-Dichlorobenzoyl) peroxide (DCBP)

DCBP or bis(2,4-dichlorobenzoyl) peroxide is one of the most widely used organic peroxides in the production of silicone extrusion products at low temperatures. DCBP is capable of creating crosslinks in extruded silicone rubbers even at low temperatures. Unlike other peroxides, DCBP does not require the presence of unsaturated alkyl or vinyl groups in the rubber structure to work effectively. The curing process usually involves the “Hot-air vulcanization” method when using DCBP.

Properties of DCBP

DCBP peroxide is a white and pasty material, which is insoluble in water and ethanol while soluble in aromatic solvents. It is important to store peroxide in a closed and well-ventilated area below 30 degrees Celsius because it can catch fire or explode when exposed to heat and direct sunlight.

The half-life of DCBP

The half-life of DCBP is 10 hours at 37°C, 1 hour at 55°C, and 1 minute at 112°C. The half-life means that at a temperature of 37 degrees Celsius, 10 hours are required for half of the peroxides to decompose and turn into radical structures.

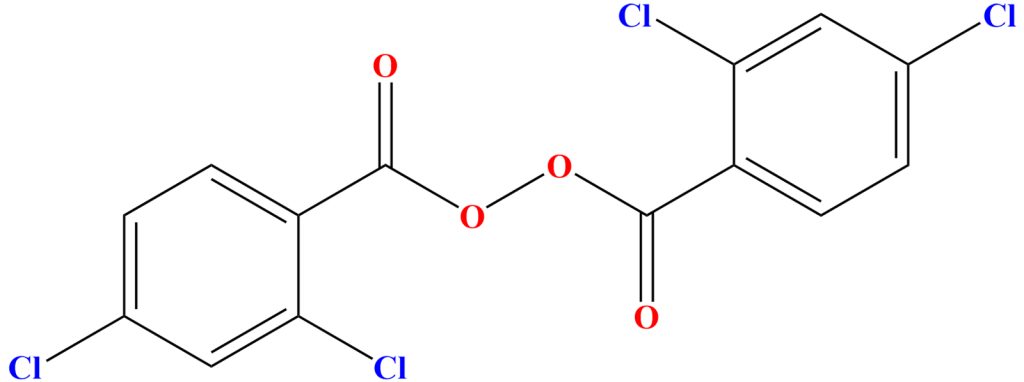

Chemical Structure of DCBP

In the chemical structure of DCBP, like other peroxides, there are two oxygen atoms connected with a weak covalent bond, and two dichlorobenzene groups are also connected to the oxygens.

Technical Specification of DCBP

Chemical formula | C14H6Cl4O4 |

Molecular weight | 380.007 g/mol |

Boiling point | Decomposes below the boiling point |

Decomposition temperature | Start at 60 °C |

Flash point (closed cup) | 194.1 °C |

Vapor pressure | 0.009 Pa (at 25 °C) |

Application of DCBP

DCBP is a curing agent that is mostly used in silicone rubber production. It is preferred over other peroxides because it has the lowest activation temperature and the highest curing speed. Due to its properties, DCBP is frequently used for extrusion products and is an ideal option for fast-curing thin cross-section products.

Vulcanization of Silicone Rubbers by DCBP

The curing process for silicone using DCBP is similar to other peroxides, but requires less time and lower temperatures to convert DCBP into radical structures. You can find more information about this process in the peroxides section.

We are here to guide you and provide advice