What is Nitrile Rubber?

Nitrile rubbers (NBR) are copolymers of butadiene and acrylonitrile, offering oil resistance and various properties. They come in ‘hot’ and ‘cold’ types, with the former having higher strength and being harder to process. Commercial grades vary in acrylonitrile content from 18% to 50%. Nitrile rubber can be cured using sulfur or peroxides. It finds wide applications in sealing, hoses, belts, soles, and as latex.

Home / NBR

NBR

Nitrile Rubbers are copolymers of butadiene and acrylonitrile which are produced by emulsion polymerization; ‘hot’ and ‘cold’ polymerized types are available. The ‘hot’ polymerized types generally have higher green strength and are slightly harder to process than ‘cold’ copolymers. The introduction of acrylonitrile into the polymer backbone imparts oil resistance and affects many other properties.

Grades of NBR

Grades which vary in acrylonitrile (ACN) content from 18-50% are commercially available, the percentage of acrylonitrile present forming the basis of the following grade descriptions.

Degree | Percentage of ACN |

Low | 18-24% |

Medium low | 26-28% |

Medium | 34% |

Medium High | 38-40% |

High | 50% |

Properties of NBR (Nitrile Rubber)

Many properties are influenced by the acrylonitrile content, e.g. (Acrylonitrile content 18 → 50)%

- Oil resistance improvement

- Fuel resistance improvement

- Tensile strength improvement

- Hardness increase

- Abrasion resistance improvement

- Gas impermeability improvement

- Heat resistance improvement

- Low temperature flexibility improvement

- Resilience improvement

- Plasticizer compatibility

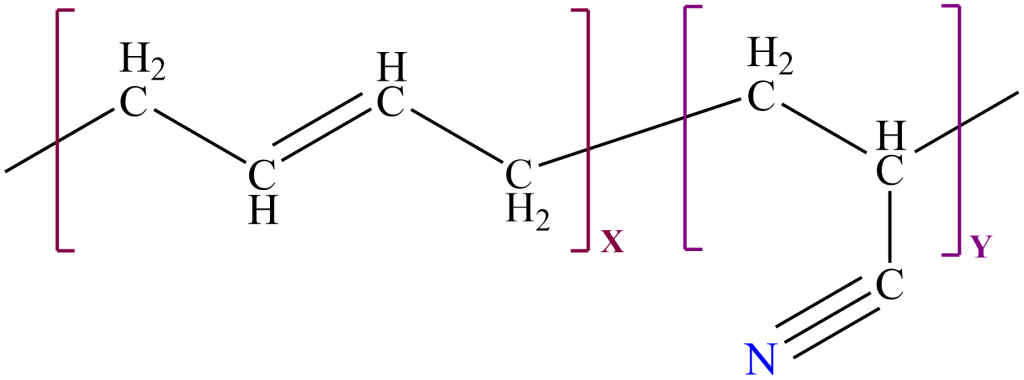

Chemical Structure of NBR

Curing System of Nitrile Rubber

Nitrile rubber can be cured by Sulphur, Sulphur donor systems and peroxides. However, the solubility of Sulphur in nitrile rubber is much lower than in NR, and a magnesium carbonate coated grade (Sulphur MC) is normally used; this is added as early in the mixing cycle as possible. Less Sulphur and more accelerator than are commonly used for curing natural rubber is required. A cadmium oxide/magnesium oxide cure system gives improved heat resistance, but the use of cadmium, a heavy metal, will increasingly be restricted.

Application of NBR

Nitrile rubber, due to its oil resistance, is widely used in sealing applications, hose liners, roll coverings, conveyor belts, shoe soles and plant linings. Nitrile rubber is also available as a latex.

Buy NBR from Sinoxe

As an industry leader, Sinoxe specializes in providing high-quality NBR and exceptional customer services. By closely collaborating with leading manufacturers and implementing state-of-the-art production processes, we guarantee to deliver products that meet international standards.

For further information, pricing, and sales conditions, please contact our sales team. We are delighted to work with you to fulfill your import requirements. Let us know how we can assist you in achieving your goals.

We are here to guide you and provide advice