What is Precipitated Silica?

Precipitated silica, also known as hydrated silica or silica gel, is a form of synthetic amorphous silica. It is produced through a chemical process known as precipitation, where a solution of sodium silicate is acidified to form a gel-like precipitate.

Home / Precipitated Silica

Properties of PPT

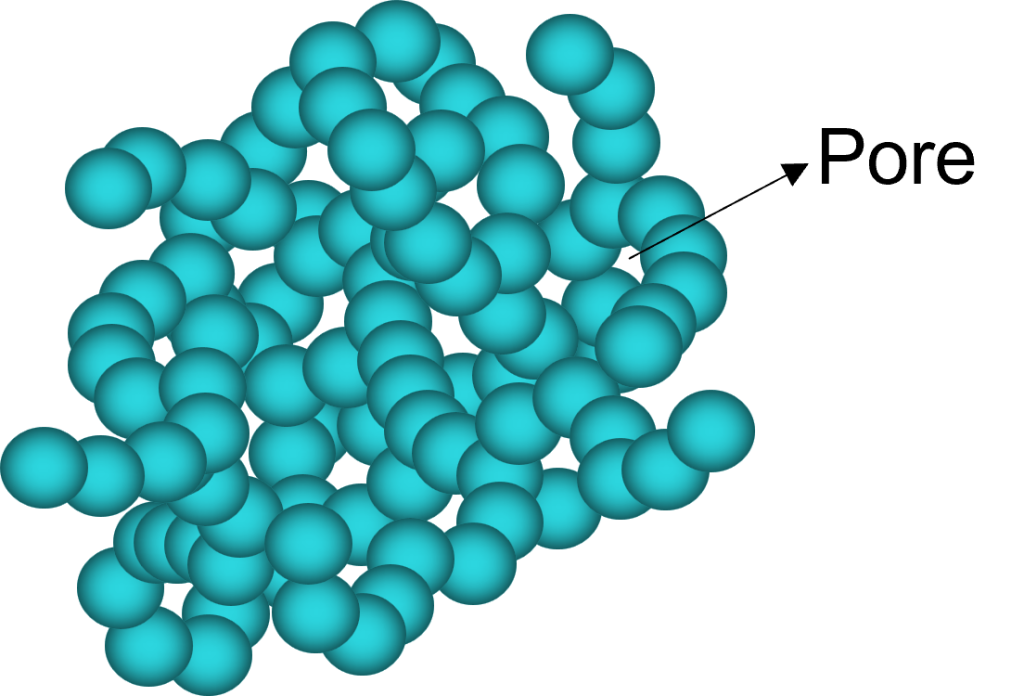

High Surface Area and Porous Structure: Precipitated silica possesses a high surface area, which is a result of its porous structure. The high surface area allows for increased adsorption and absorption capacity, controlled release of substances in various applications, making it effective in applications such as desiccants, drying agents, and adsorbents.

Reinforcing Filler: Precipitated silica acts as a reinforcing filler in rubber and plastic applications. It improves the mechanical properties of these materials, such as tensile strength, tear resistance, and abrasion resistance. This feature makes it a valuable component in the production of tires, belts, hoses, and other rubber products.

Thixotropic Behavior: Precipitated silica exhibits thixotropic behavior, meaning it becomes less viscous when agitated or sheared. This property makes it useful as a thickening agent in liquids, providing viscosity control, and as a suspending agent, preventing settling or sagging of formulations, such as paints, adhesives, and coatings.

Surface Reactivity: The surface of precipitated silica particles is highly reactive, allowing for interactions with other substances. This reactivity makes it useful as a catalyst support in various chemical reactions. The surface can also be modified with functional groups or coatings to enhance its compatibility with specific applications or to introduce specific properties.

Precipitated silica has a high surface area and a porous structure, which gives it unique properties such as high absorbency and reinforcing capabilities. Precipitated silica can be customized during the manufacturing process to achieve specific characteristics such as particle size, surface area, and pore structure, making it suitable for a wide range of applications.

Precipitated Silica Structure

The structure of precipitated silica is amorphous, meaning it lacks a well-defined crystalline structure. It consists of silicon dioxide (SiO2) units arranged in a three-dimensional network. The lack of a crystalline structure in precipitated silica contributes to its unique properties, such as high absorbency, reinforcing capabilities, and surface reactivity. The structure of precipitated silica is characterized by a high surface area and a porous nature. This porous structure arises from the interconnected void spaces between the silica particles. The size and distribution of these pores can vary depending on the specific manufacturing process and conditions employed.

Precipitated Silica Application and Uses

Precipitated silica has a wide range of applications and uses across various industries. Some of its primary applications include:

Rubber Industry: Precipitated silica is extensively used in the rubber industry as a reinforcing filler. It enhances the mechanical properties of rubber products, such as tires, belts, hoses, and seals, by improving their strength, tear resistance, and abrasion resistance.

Coatings and Paints: It is used as a matting agent in coatings and paints to create a matte or satin finish. Precipitated silica helps to control the gloss level and improve the scratch resistance of the coatings.

Adhesives and Sealants: Precipitated silica is added to adhesives and sealants to enhance their strength, flexibility, and adhesion properties. It also improves the thixotropic behavior, preventing sagging or settling of the formulations.

Plastics Industry: It is used as an anti-blocking agent and flow aid in plastic films, preventing them from sticking together. Precipitated silica also improves the mechanical properties and dimensional stability of plastic products.

Precipitated Silica Production Process

Precipitated silica is a synthetic form of amorphous silica, also known as hydrated silica or silica gel. It is produced through a chemical process called precipitation, where a solution of sodium silicate is acidified to form a gel-like precipitate. The resulting precipitate is then washed, dried, and milled to obtain the final product, which is a fine white powder.

Technical Specification of Precipitated Silica H-620

Inspection | Index value |

Total specific surface area(m2 /g) | 150~200 |

Loss on ignition(%) | ≤ 7.0 |

Silica content(%) | ≥ 98 |

pH value | 6.0~7.5 |

Median particle size(µm) | 9~13 |

We are here to guide you and provide advice