What is Fumed Silica?

Fumed silica is a nanostructured form of silicon dioxide produced through the hydrolysis of silicon compounds in a flame of hydrogen and oxygen. It has a high surface area and particle size ranging from 1 to 100 nanometers.

Home / Fumed Silica

Fumed Silica

Fumed silica, also known as pyrogenic silica, is a nanostructured form of silicon dioxide (SiO2) that is produced by the hydrolysis of silicon compounds in a flame of hydrogen and oxygen. The particles of fumed silica have a three-dimensional network structure, and they are interconnected to form aggregates with high surface area. The particle size of fumed silica typically ranges from 1 to 100 nanometers, which allows it to remain suspended in liquids or adhere to solid surfaces.

Application of Fumed Silica

- Fumed silica is widely used as a rheology modifier and thickening agent in various industries, including paints, coatings, adhesives, and sealants. It helps control viscosity, improve sag resistance, and enhance the stability of these formulations.

- Due to its high surface area and porosity, fumed silica is utilized as a reinforcing filler in rubber and elastomer applications. It improves mechanical properties such as tensile strength, tear resistance, and abrasion resistance.

- In the pharmaceutical industry, fumed silica is used as a pharmaceutical excipient in solid dosage forms, such as tablets and capsules. It aids in improving powder flow, compressibility, and dissolution rate of active pharmaceutical ingredients.

- Fumed silica is employed in the production of silicone rubber and silicone sealants. It enhances the mechanical strength, thermal stability, and electrical insulation properties of these materials.

- Fumed silica is utilized in the manufacture of adhesives and sealants to improve bonding strength, adhesion to different substrates, and resistance to environmental factors like moisture and temperature.

Fumed Silica Structure

The structure of fumed silica consists of nanoscale particles that form a three-dimensional network. These particles are highly porous and have a large surface area. Here is a description of the structure of fumed silica:

Three Dimensional Network of Fumed Silica

Technical Specification of Fumed Silica SN-200

Item | Index |

Surface Area (m2/g) | 185-225 |

Ignition loss % | 2.5 |

Silicone oxide % | 99.8 |

PH Value in Aqueous Dispersion | 3.7~4.5 |

Tap density(g/dm3) | 30~60 |

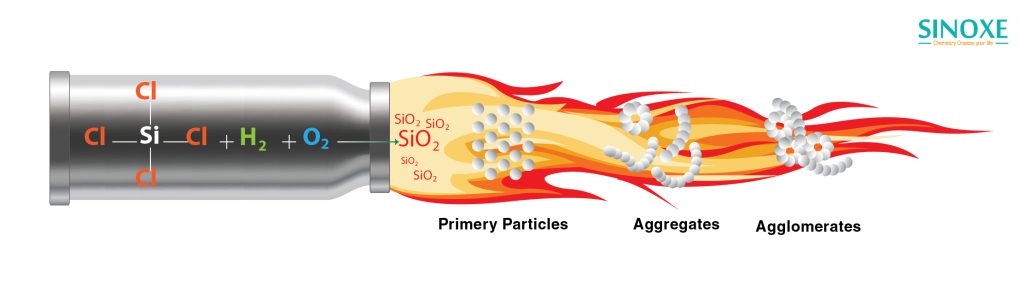

Fumed Silica Production Process

The production process of fumed silica involves the hydrolysis of silicon compounds in a flame to produce nanostructured silicon dioxide particles. Here is a general description of the fumed silica production process:

- Feedstock Preparation: The process begins with the preparation of the feedstock, which usually consists of silicon compounds such as silicon tetrachloride (SiCl4) or silicon alkoxides. These compounds are typically derived from silica-rich materials like quartz or silicon metal.

- Flame Hydrolysis: The feedstock is introduced into a high-temperature flame composed of hydrogen and oxygen. The silicon compounds undergo a chemical reaction known as hydrolysis, where they react with water vapor (H2O) in the flame to form silicon dioxide (SiO2) particles.

- Nucleation and Growth: In the flame, the hydrolyzed silicon compounds undergo nucleation, which is the formation of small primary particles. These primary particles then grow by the condensation of additional silicon dioxide molecules onto their surfaces.

- Aggregation and Particle Formation: As the particles continue to grow, they tend to aggregate, forming larger structures known as aggregates. Aggregation occurs due to van der Waals forces and other interparticle interactions. The aggregates consist of interconnected primary particles, creating a porous network structure.

- Collection and Filtration: The cooled fumed silica particles are collected using a filtration system. This typically involves passing the particles through a series of filters or cyclones, where the larger aggregates are separated from the gas stream and collected as a powder.

Bulk Purchase of Fume Silica from Sinoxe

As a reputable manufacturer and supplier of Fumed Silica products, specifically the SN-200 model, we are ready to cater to various industries.

SN-200, with specifications and features similar to the above text, is suitable for use in industries such as paints, coatings, adhesives, and sealants as a rheology modifier and thickening agent.

By purchasing in bulk from us, you will benefit from increased productivity and competitive pricing. Our sales team at Sinoxe is ready to handle your inquiries and provide bulk purchase terms.Enjoy the added advantages that come with buying in bulk from us. Contact us for ordering and further information.

We are here to guide you and provide advice